Technical ceramics in particular Al2O3

Technical ceramics are high-performance materials that can be divided into four material groups: silicate ceramics, oxide ceramics, non-oxide ceramics (carbides and nitrides) and piezoceramics. As a rule, they are formed at room temperature from a raw mass formed from ceramic powder, organic binder and liquid and only acquire their typical material properties in a sintering process at high temperatures.

Alumina with an Al2O3 content of more than 80% to over 99% is the technically most important oxide ceramic material. It is characterized by

- high strength and hardness,

- high wear resistance and corrosion resistance,

- high thermal conductivity,

- excellent insulating properties,

- high toughness and

- high temperature strength.

Key properties by purity:

| Property | 96 % (C795) | 99,8 % (C799) |

|---|---|---|

| Density | 3,75 g/cm³ | 3,96 g/cm³ |

| Flexural strength | 310 MPa | 630 MPa |

| Weibull modulus | 13 | 15 |

| Compressive strength | 2500 MPa | 4000 MPa |

| Fracture toughness | 4,0 MPam½ | 4,3 MPam½ |

| Young's modulus | 350 GPa | 406 GPa |

| Vickers hardness HV1 | 1620 MPa | 2000 MPa |

| Max. Operating temperature | 1600°C | 1700°C |

| Melting point | 2054 °C | |

| Boiling point | 2980 ± 60 °C | |

- in electrical engineering,

- in electronics

- in mechanical and plant engineering

- in chemical and process engineering

- in medical technology,

- in high-temperature technology.

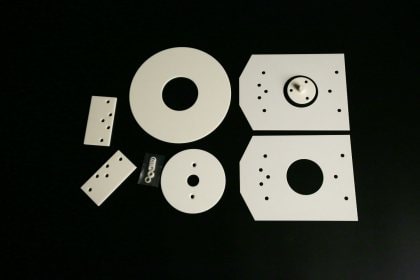

Our range of products includes semi-finished products such as blocks, rods, plates and discs as well as thermocouple protection tubes, insulators, radiant tubes and customer-specific CNC-manufactured components according to drawings.